Progress in Irradiation and Corrosion Resistant High-temperature Nickel Base Alloys

Recently, the alloy research team of Shanghai Institute of Applied Physics (SINAP), Chinese Academy of Sciences (CAS) has made important progress and successfully developed Y2O3 dispersion strengthened nickel base alloy with excellent irradiation and molten salt corrosion resistance. The research result entitled “A potential candidate structural material for Molten Salt Reactor: ODS nickel-based alloy” was published in Journal of Materials Science & Technology. The co-first author are Associate Professor Cheng Li and Guanhong Lei, Prof. Hefei Huang is the corresponding author.The structural materials of molten salt reactor (MSR) are faced with multiple environmental challenges such as strong neutron irradiation, high temperature and molten salt corrosion in the reactor. According to the MSRE report made by ORNL and the preliminary research of the material research team of SINAP, The high temperature irradiation induced embrittlement / swelling caused by neutron irradiation transmutation product He and the irradiation & corrosion synergistic damage of alloy used for core components will lead to the deterioration of alloy mechanical properties and then shorten the service life of the components. It has become one of the bottlenecks restricting the development and efficient utilization of MSR. Therefore, the research and development of new irradiation and corrosion resistant alloys has become an important issue in the application of MSR. In recent years, Prof. Hefei Huang led the team to develop irradiation-resistant carbide dispersion strengthened (CDS) nickel base alloy by powder metallurgy by adding SiC nanoparticles into nickel base alloy, which has attracted extensive attention (Journal of Materials Science & Technology 31 (2015) 923; Materials & Design 90 (2016) 359). This type of alloy was reported on the world nuclear news website in 2017.

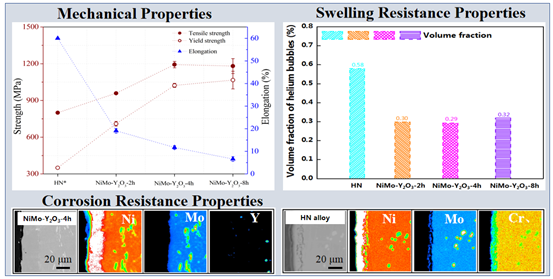

Compared with SiC nanoparticles, Y2O3 nanoparticles are precipitated after dissolution. The particles are finer and more uniform and more stable at high temperature, which lays a theoretical foundation for further improving the mechanical properties and He induced damages of the alloy. However, the presence of oxides may lead to poor molten salt corrosion resistance of the alloy. In order to verify this problem, NiMo-1wt% Y2O3 alloy was developed by powder metallurgy. The mechanical properties, irradiation resistance and molten salt corrosion resistance of the alloy were systematically investigated and compared with Hastelloy N alloy, a candidate structural material for MSR. The experimental results show that the alloy has excellent tensile strength (1193 MPa) and yield strength (1063 MPa), which are higher than Hastelloy N alloy (tensile strength of 800 MPa and yield strength of 350 MPa) and CDS alloy (tensile strength of 965 MPa and yield strength of 825 MPa). In addition, the volume fraction (~ 0.3%) of He bubbles in NiMo-Y2O3 alloy after irradiation is lower than that in Hastelloy N alloy (0.58%), which indicates that the introduction of Y2O3 nanoparticles effectively inhibits the He swelling. Moreover, NiMo-Y2O3 alloy also shows excellent resistance to molten salt corrosion, showing its great potential as a MSR structural material for core components.

This study was supported by the National Natural Science Foundation of China and the Youth Innovation Promotion Association, CAS.

Fig. 1. Mechanical, irradiation swelling and corrosion resistance of NiMo-Y2O3 alloy