Recently, the alloy research team of Shanghai Institute of Applied Physics (SINAP), Chinese Academy of Sciences (CAS) has made important progress in enhancing the resistance for Te-induced intergranular embrittlement in GH3535 alloy by modifying the alloy with trace amount of lanthanum.

The research result entitled “Influence of lanthanum element on tellurium induced embrittlement of Ni-16Mo-7Cr alloy” was published in Corrosion Science. The first author is Prof. HAN Fenfen, Prof. LENG Bing and Prof. LI Xiaoli are the corresponding authors.

Molten salt reactor (MSR), which can exploit the full potential of liquid fuel, has numerous advantages over solid fuel designs. However, there are strict requirements on the properties of metallic structural materials in MSR, owing to its extreme service conditions (high temperature at ~700oC), molten salt corrosion, and neutron irradiation environments. GH3535 alloy (Ni-16Mo-7Cr), is specifically developed for Thorium Molten Salt Reactor nuclear energy system (TMSR) in China as main structural materials due to its superior corrosion resistance and good mechanical properties. However, when the alloy is exposed to the fuel salt directly, the intergranular cracking behavior will appear. Many efforts have been confirmed that such problem is induced by the fission product of Te in the salt. Te can weaken the grain boundaries and lead to intergranular embrittlement of the alloy. That would significantly reduce the mechanical strength of the alloy, and cut down the service time of the structural components, or even lead to serious accidents of nuclear reactor.

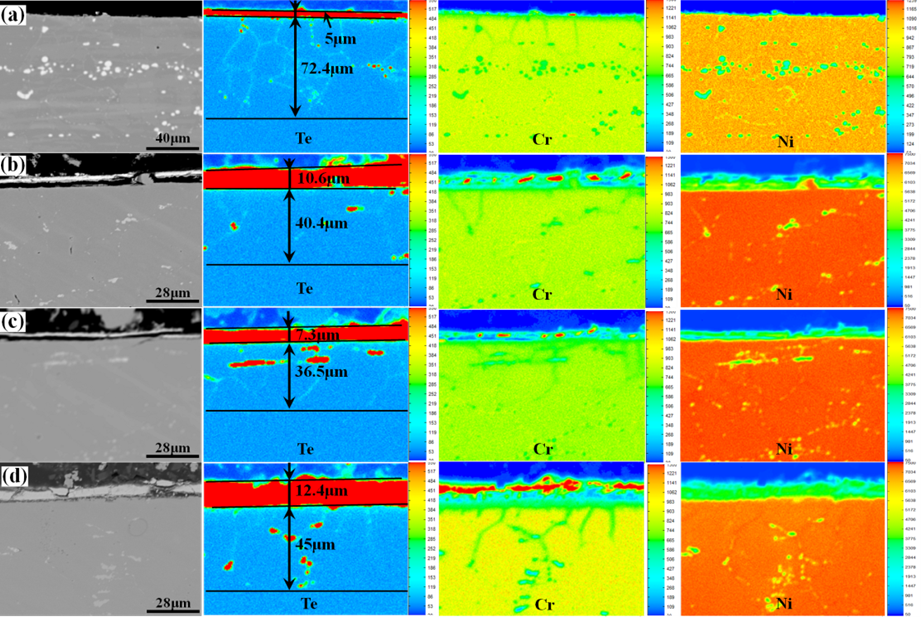

In recent years, the alloy research team has been devoted to develop Te-resistant nickel-based alloy by adding rare elements into nickel-based alloy. Among tested alloys, La-modified GH3535 alloy has better performance on intergranular cracking resistance.Under the same experimental conditions, Te diffusion depth in GH3535 alloy is ~70μm, whereas it’s only ~40μm in La-modified alloy. Therefore, the addition of La element can significantly decrease the diffusion depth of Te into the alloy, and hence improve the alloys’ intergranular embrittlement resistance. In La-modified alloys, La segregates in the surface tellurium reaction layer without forming lanthanum tellurium compounds. In addition, the second phase of LaNi5 formed on the grain boundary near the surface can react with Te to form nickel tellurides. The synergistic effect between surface segregation of La and telluride formation at grain boundaries contributes to the reduced Te diffusion depth. The optimal content of La in the alloy should be about 0.1 wt.%. Excessive La content could lead to the increase of LaNi5 phase formation, which has no beneficial effect on the improvement of mechanical properties of the alloy.

This work was financially supported by the National Natural Science Foundation of China.

Link: https://doi.org/10.1016/j.corsci.2022.110360

Fig. EPMA morphology and the element distribution of the cross-sectional specimens annealed at 800oC for 100h in Te vapor: (a) GH3535 alloy, (b) 0.1La modified alloy, (c) 0.15La modified alloy, (d) 0.3La modified alloy