Recently, the alloy research team of Shanghai Institute of Applied Physics (SINAP), Chinese Academy of Sciences (CAS) has made progress in further understanding the corrosion behaviors of two nickel-based alloys, GH3535 and Inconel 625 alloys, in molten nitrate salts. The research result entitled “The characterization of corrosion layers of GH3535 and Inconel 625 alloys in molten KNO3-NaNO3 salts at 500 ℃” has been published in Corrosion Science. Dr. LIU Chengpeng is the first author, and Prof. LENG Bin is the corresponding author.

As the molten nitrate salts are widely used for thermal energy storage and transfer, and has a strong ability to trap the tritium, it is a promising candidate medium for the third loop of the molten salt reactor (MSR). GH3535 alloy is currently the key structural material for MSR due to its comprehensive performance, especially excellent resistance to fluoride molten salts corrosion, however the corrosion resistance of this alloy in the molten nitrate salts is unclear. In order to select proper structural materials for the third loop, the corrosion performance of GH3535 alloy in molten nitrate salts (40 wt.% KNO3-60 wt.% NaNO3) has been evaluated by immersion test at 500℃ for 500 h, along with the Inconel 625 alloy as the reference material. The characterization of corrosion layers is conducted by advanced electron microscopy technology.

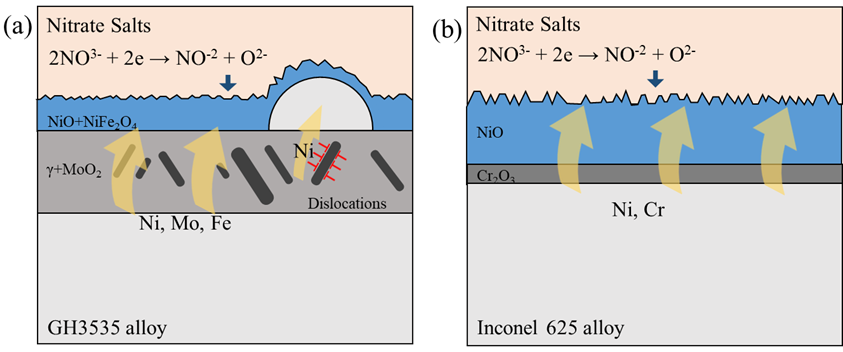

The results show the outer and inner corrosion layer of GH3535 alloy consist of NiO+ NiFe2O4 and γ+MoO2, respectively. Besides, the stress induced by internal oxidation promotes Ni outward diffusion hence the surface γ/NiO core-shell structured particle formation. However, the outer and inner corrosion layer of Inconel 625 alloy consist of NiO and Cr2O3, respectively. The corrosion difference between the two alloys is caused by the higher content of Mo in GH3535 alloy whilst the higher content of Cr in Inconel 625 alloy. The corrosion layer of GH3535 alloy is slight thicker than that of Inconel 625 alloy, while the extent of corrosion is still minor, suggesting that GH3535 alloy can serve as a promising candidate structural material for the MSR’s third loop containing molten nitrate salts.

This work was supported by the Strategic Priority Research Program of the Chinese Academy of Sciences and the Youth Innovation Promotion Association, CAS.

Fig. The schematic diagrams of corrosion mechanism of (a) GH3535 and (b) Inconel 625 alloys in the molten nitrate salts.