Progress in the study on the interaction between SiC and Ni-based alloy in molten FLiNaK salt

The corrosion team of Shanghai Institute of Applied Physics, Chinese Academy of Sciences made an important progress in the studies on the interaction between SiC and Ni-based alloy in molten FLiNaK salt. Xinmei Yang and Xingtai Zhou helped the students (Wandong Xue, Xiaodong Wang, and Miaomiao Hu) to study the corrosion of SiC in molten FLiNaK salt. They contribute a lot to the application of SiC to molten salt reactors.

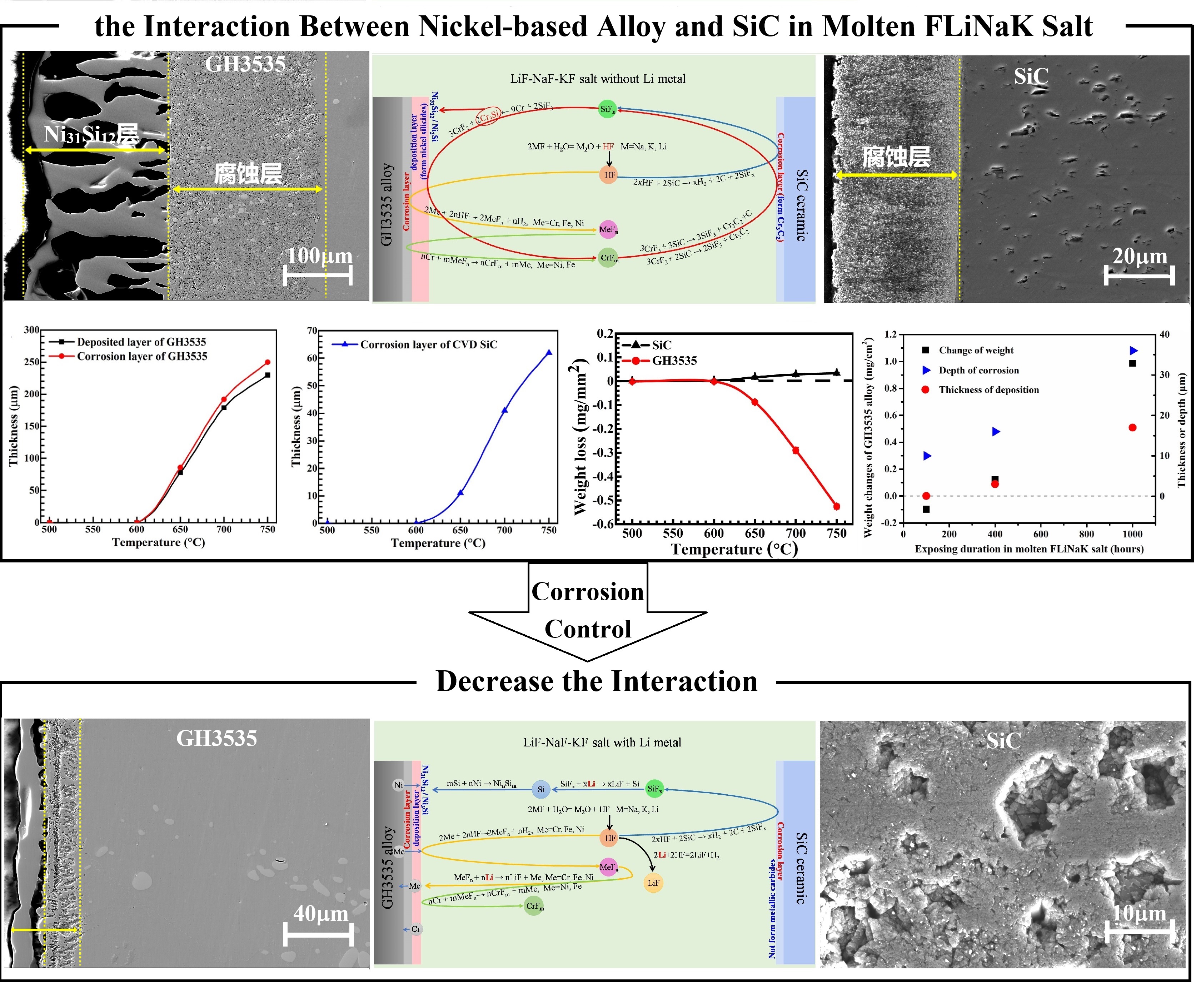

SiC-based materials have potential applications to the nuclear reactors due to their superior high-temperature properties and irradiation resistance. For the application of SiC to molten salt reactor, the corrosion of SiC and it’s compatibility with the structural material are critical issues. This team studied the corrosion of SiC in molten FLiNaK salt. Results indicate that CVD SiC and pressureless sintered SiC have superior corrosion resistance in the purified FLiNaK salt. However, SiC can interact with the metallic materials to aggravate their corrosion in molten FLiNaK salt. It’s found that the temperature is one factor to affect the interaction between SiC and metallic materials in molten FLiNaK salt. SiC-based materials began to interact with the metallic materials at the temperature more than 600 ℃. The corrosion depth of SiC and nickel-based alloy is increasing with the temperature. The impurity in molten FLiNaK salt is another crucial factor to drive the interaction between SiC and nickel-based alloy. Firstly, the impurities in molten FLiNaK salt drive the corrosion of SiC and alloy to form the Si-containing and Cr-containing corrosion products. Then, the Cr-containing corrosion products react with SiC to form chromium carbide, and the Si-containing corrosion products react with the nickel-based alloy to form nickel silicide. In a closed environment, these reactions can continuously form the Cr-containing and Si-containing corrosion products to drive the continuous corrosion of SiC and nickel-based alloy. The corrosion of SiC and nickel-based alloy is severe when they are coexisting in molten FLiNaK salt. Therefore, this team studied the method to decrease the interaction between these materials. Results indicate that the active metal, Li, can be used to decrease the interaction and the corrosion depth of nickel-based alloy to ~30 μm from ~200 μm, and inhibit the formation of chromium carbide. These studies on the mechanism of interaction between SiC and nickel-based alloy in molten FLiNaK salt and the method to inhibit the interaction are important for the application of SiC-based materials to the molten salt reactors.

Above studies were mainly supported by the National Natural Science Foundation of China, the “Transformational Technologies for Clean Energy and Demonstration”, Strategic Priority Research Program of Chinese Academy of Sciences, and the Strategic Priority Research Program of the Chinese Academy of Science.

Fig. 1 The interaction between SiC and nickel-based alloy in molten FLiNaK salt with and without active metal Li.

Links:

https://doi.org/10.1016/j.mtcomm.2024.109531

https://doi.org/10.1016/j.corsci.2023.111075

https://doi.org/10.1016/j.corsci.2022.110260

https://doi.org/10.1016/j.nucmat.2018.12.035