There are two main viewpoints on the origin of metallurgy in China: exotic and indigenous. Under the guidance of Prof. Changsui Wang, Dr. Xiaopan Fan of GUCAS proved the brass unearthed at Jiangzhai site(4700-400BC,the earliest copper-based alloy excavated to date in China) was produced by a solid-state reduction process through a series of simulating experiments and analysis of μ-X-ray fluorescence at SSRF. It is interesting that the date of the earliest copper alloy found in China should be so close to that of its counterpart from Western Asia. Although the alloy from China is chemically very different from the alloy in Western Asia (arsenical bronze) the production method of these two very early artificial alloys might have been much the same: solid-state reduction of mixtures of appropriate minerals. This fact is consistent with an indigenous origin in China. Their research has been published on, 2012 in Journal of Analytical Atomic Spectrometry.

In order to explore the production process of early brass, we designed and carried out simulation experiments according to raw materials, physicochemical principle of brass production and possible production process of early brass.The procedures of simulation experiment were: mix calamine, malachite(or copper) and charcoal in a certain proportion, then put the mixture into lidded crucibles, and place the crucibles in a muffle furnace, and heat them in different temperatures(750℃-1000℃) and different periods(0-48h). 171 runs were performed.

The results of XRF and metallographical microscope showed that: bulk brass(brass obtained by a solid-state reduction process) and brass through a melting process can be obtained by the raw materials of calamine, charcoal and malachite; Only one kind brass(brass through a melting process) can be obtained by the raw materials of calamine, charcoal and copper.

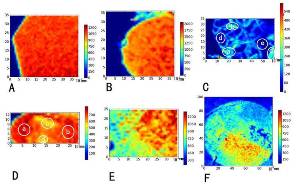

Four runs(sample1: brass through a melting process obtained by the raw materials of calamine, charcoal and copper, sample2: brass through a melting process obtained by the raw materials of calamine, charcoal and malachite, sample3and4:bulk brass obtained by the raw materials of calamine, charcoal and malachite) were chosen for the synchrotron radiation μ-XRF mapping study. The zinc and lead distribution patterns suggest that zinc would be evenly distributed in brass specimens prepared by a melting process regardless of whether the alloy was obtained by cementation or by smelting of calamine and malachite, lead metal scattered at some spots. On the other hand the zinc distribution in bulk brass made by a solid-state reduction process was obviously not uniform, the zinc content in different regions varied markedly; and the lead content of different regions was quite distinct, not uniform.

Analysis by μ-XRF of the brass unearthed at the Jiangzhai site showed that the distribution pattern of lead as well as zinc was similar to that of the brass made by a solid-state reduction process, but significantly different from that of the brass made by a melting process. Our results suggest that ancient brass unearthed at the Jiangzhai site was probably obtained by a solid-state reduction process.

This research provided hard scientific evidence for the indigenous origin of metallurgy in China. Nobody has utilized Synchrotron Radiation m-X-ray fluorescence to infer metallurgical processing of ancient alloys before. It is sure that Synchrotron Radiation m-X-ray fluorescence as a non-invasive analytical technique will be used to analyze production process of other ancient alloys like arsenic copper.