Significant progress in Understanding Stress-assisted Cracking behaviors of Materials for Molten Salt Reactors

Recently, the researchers at the State Key Laboratory of Thorium Energy, Shanghai Institute of Applied Physics (SINAP), Chinese Academy of Sciences, have made significant progress in understanding the stress assisted cracking behavior of structural materials for molten salt reactors (MSRs). The research result, entitled "Understanding of the stress assisted cracking behavior of Ni-based alloy GH3535 in molten LiF-NaF-KF salt" has been published in Corrosion Science (2025, 254: 113038), reveals critical insights into the failure mechanisms of Ni-based alloy GH3535 under combined molten salt corrosion and tensile stress.

Stress corrosion cracking (SCC) is an important failure mechanism for materials subjected to the combined effects of corrosive environments and tensile stress. SCC incidents occurred unpredictablely in commercial reactors, causing significant economic losses. MSRs operate at much higher temperatures than light-water reactors, with more demanding conditions, exposing structural materials to synergistic effects of corrosion and stress during service. This poses a long-term risk of stress corrosion cracking. However, research progress in this field has been slow due to experimental difficulties, such as the application of stress to specimens at high temperatures and the high sensitivity of molten salt corrosion to water and oxygen.

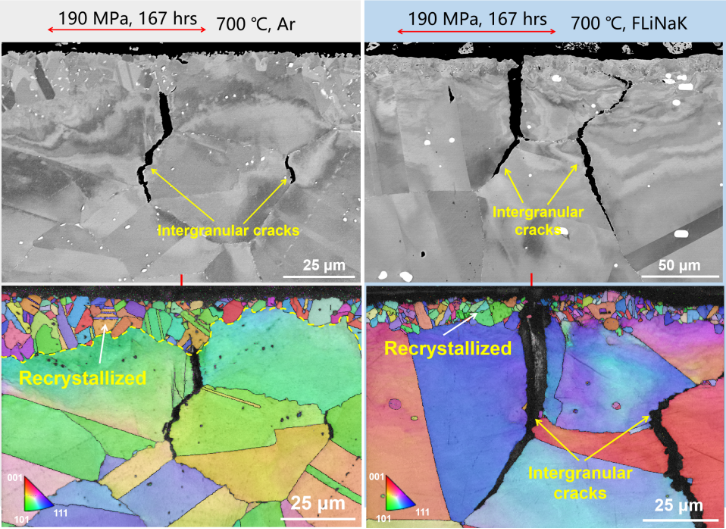

Figure 1. Crack initiation and microstructural features in the cracked initiation zone of GH3535 alloy in argon and molten salt environments.

To address these challenges, the SINAP team developed a novel experimental setup applying constant tensile stress in molten LiF-NaF-KF (FLiNaK) salt under inert gas protection. Their key discoveries include:

Accelerated creep rates in molten salt compared to argon environments;

Intergranular crack initiation beneath the surface, with more cracks propagating outward in molten salt (Figure 1).

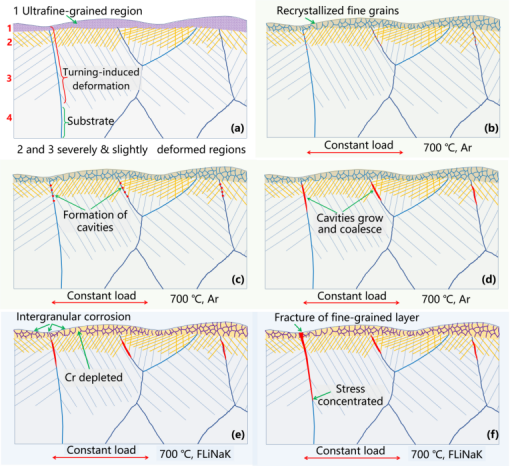

A dual cracking mechanism:

1. Internal creep cracks form in machining-induced deformation zones.

2. Stress corrosion cracking in the surface recrystallized micron-sized grain region, and linking of the internal creep cracks with surface stress corrosion cracks in the molten salt (Figure 2).

Figure 2 Cracking mechanisms for alloy GH3535 tested under the combined effects of Ar/molten salt environment and tensile stress

Historically, tellurium (Te)—a fission product—was blamed for intergranular cracking in MSR materials ("tellurium embrittlement"). However, this study demonstrates that manufacturing-induced surface defects can trigger cracking even without molten salt or Te, emphasizing the need for optimized fabrication processes alongside material composition improvements.

This work shifts the focus from solely material composition to manufacturing quality control, offering a new pathway to enhance component reliability in MSRs.

The study was supported by the CAS Talent Introducing Program and the National Natural Science Foundation of China.

Full article link: https://www.sciencedirect.com/science/article/pii/S0010938X25003658