Significant Research Progress in Material Applications Under High-Temperature Molten Salt Environments

Since 2024, the Alloy Process Group of the Molten Salt Mechanical Department, Shanghai Institute of Applied Physics(SINAP) has conducted systematic research on the service behavior of structural materials in high-temperature molten salt environments. The team has published three high-quality papers consecutively in internationally journals including Journal of Energy Storage and Materials, successfully addressing three key scientific challenges in material applications under high-temperature molten salt environments.

I. Revelation of the Critical Role of “Thermal-Induced Phase Transformation” in Molten Salt Corrosion

The effect of thermal-induced phase transformation on the corrosion behavior of Inconel 625 alloy in NaCl-KCl-MgCl₂ molten salt. Journal of Energy Storage, 100 (2024) 113456. https://doi.org/10.1016/j.est.2024.113456 (IF: 9.8)

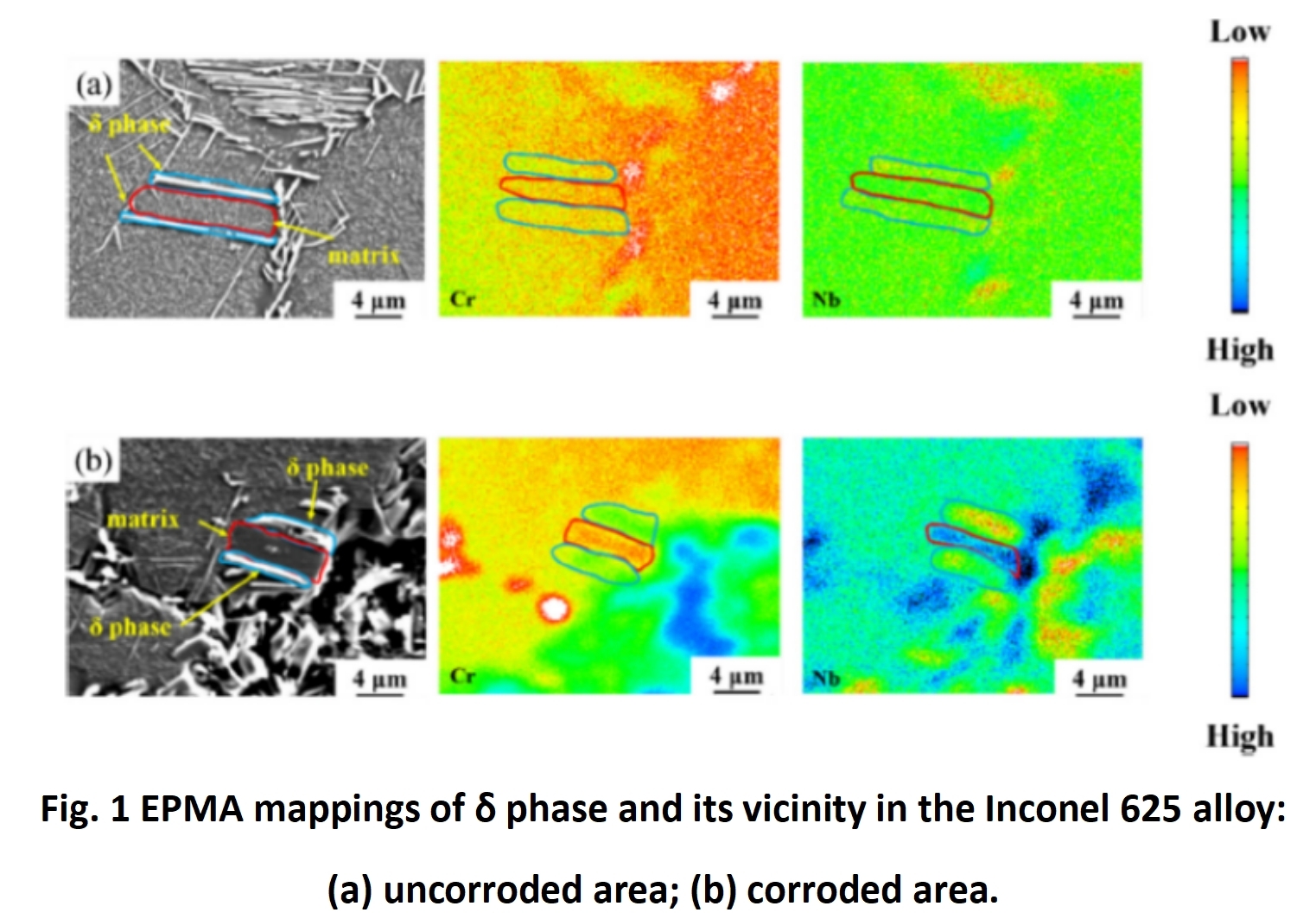

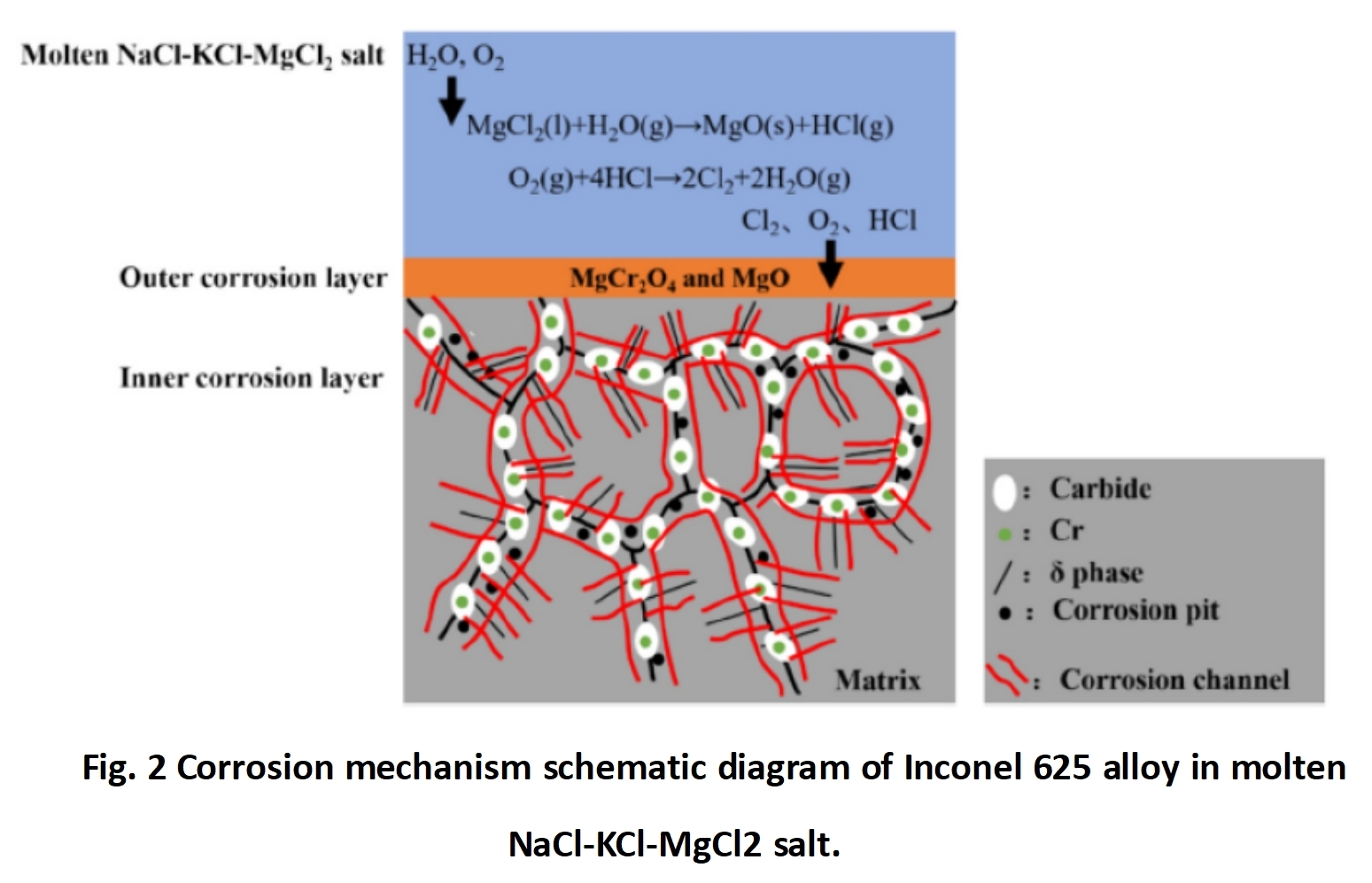

This study first proposes that thermal-induced phase transformation is a non-negligible and critical factor during the high-temperature molten salt corrosion processes. The research discovered that in Inconel 625 alloy, long-term thermal exposure induces the precipitation of chain carbides at grain boundaries and the formation of needle-like δ phases. These phase-transformed structures act as preferential corrosion channels in the molten salt environment, significantly accelerating material degradation. The study explicitly points out that the thermal stability of materials should be a key design parameter in the design of alloys for molten salt service, providing new theoretical foundations for composition optimization and microstructure control of molten salt-resistant alloys.

II. A Novel Mechanical Evaluation Method Based on Decoupling Molten Salt Corrosion and Thermal Aging Effects

A new method to study the corrosion behavior in chloride salts and its effects on tensile properties. Journal of Energy Storage, 144 (2026) 119712. https://doi.org/10.1016/j.est.2025.119712 (IF: 9.8)

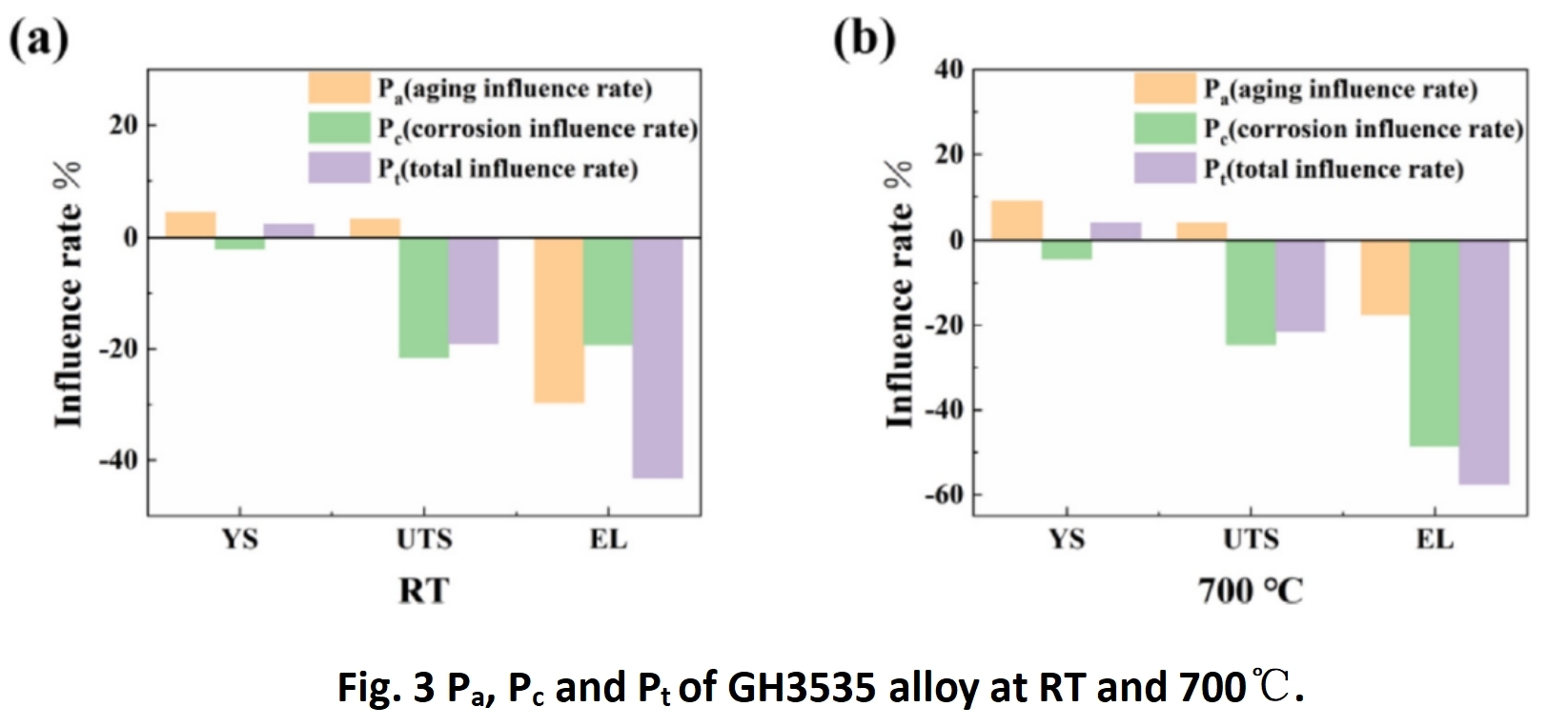

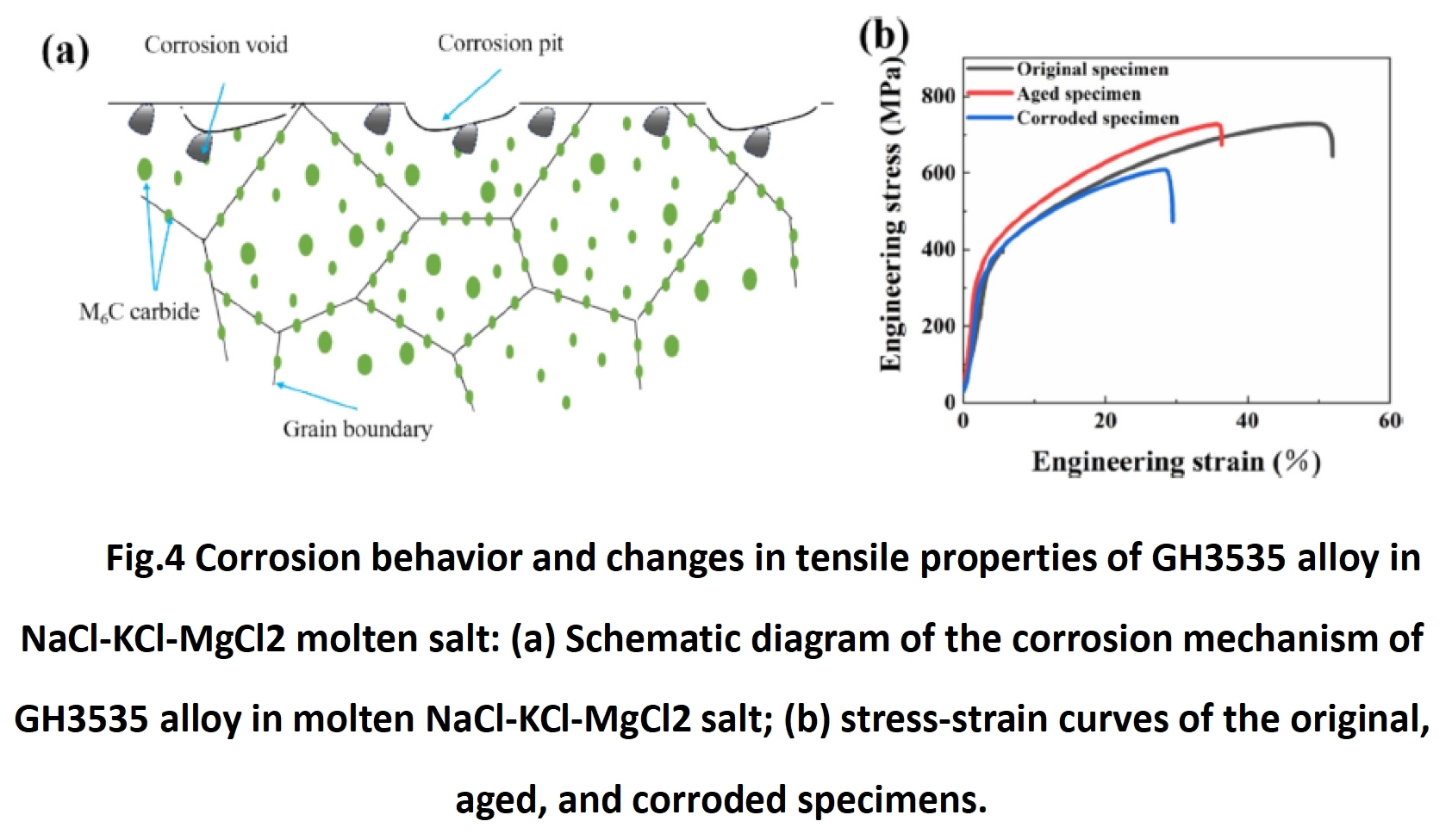

To address the long-standing challenge of distinguishing between molten salt corrosion and thermal aging effects, this study first introduces the concepts of "corrosion influence rate" and "aging influence rate," establishing a novel method to quantitatively decouple the individual effects of these two factors on mechanical properties. The results demonstrates that molten salt corrosion primarily acts on the material surface, inducing surface defects and crack initiation, which significantly reduces material elongation. Thermal aging, conversely, triggers internal phase transformations, exerting a more pronounced effect on material strength. This method provides a new research paradigm for distinguishing degradation mechanisms and evaluating service life under complex operating environments, facilitating understanding of the fundamental scientific nature of individual factors and demonstrating excellent potential for broader applications.

III. Systematic Comparison of Corrosion Behavior in Molten Salt Vapor, Liquid Phase, and Vapor-Liquid Interface

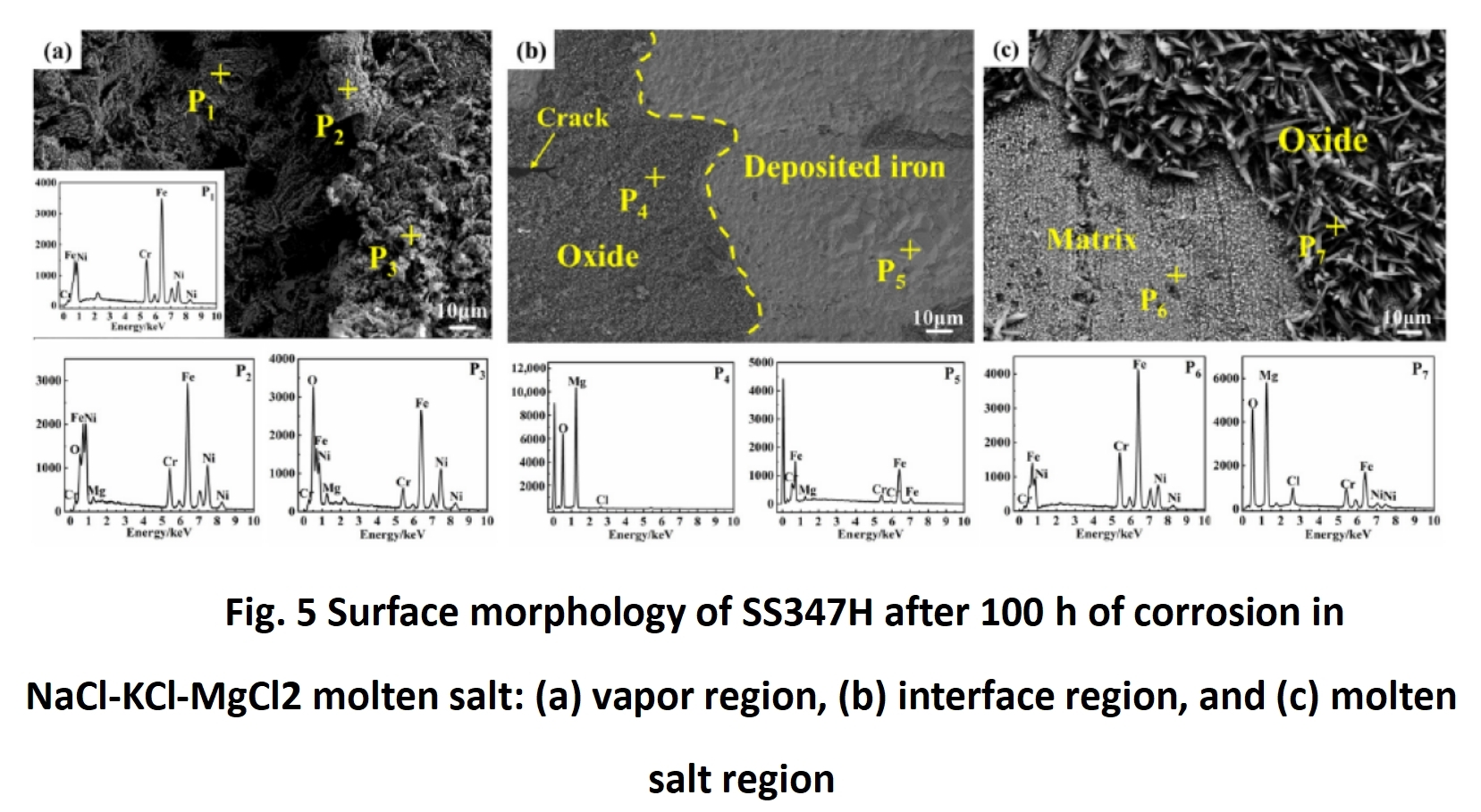

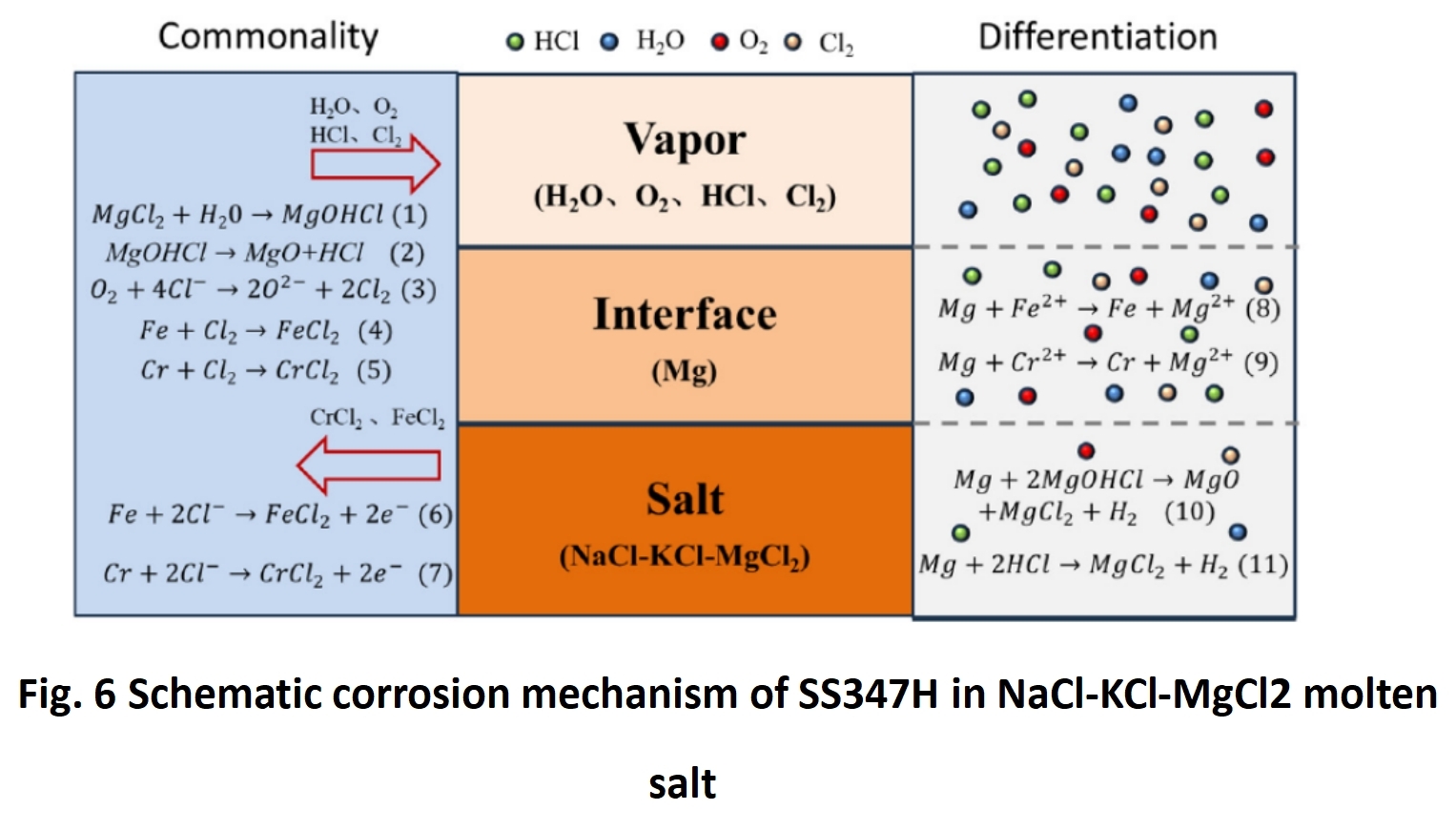

Corrosion behavior of 347H stainless steel in NaCl-KCl-MgCl₂ molten salt: vapor, liquid, and interface comparison. Materials, 18 (2025) 3412. https://doi.org/10.3390/ma18143412 (IF: 3.2)

This study, for the first time within a single system, compares the differences in corrosion behavior among three typical service regions: molten salt vapor, molten salt liquid phase, and the vapor-liquid interface. The findings reveal that corrosion is most severe in the molten salt vapor region; material corrosion is least severe within the molten salt liquid phase; and at the vapor-liquid interface, significant metal ion displacement and deposition phenomena occur, accompanied by enrichment of Fe and Cr elements. The study explicitly proposes that engineering design should pay particular attention to the corrosion failure risk posed by molten salt vapor to structural materials, providing important guidance for the structural layout and protection strategies of molten salt thermal energy storage devices and high-temperature molten salt systems.

In summary, the Alloy Process Group has conducted systematic research through the deep integration of materials science and molten salt chemistry. For the first time, the team has established a new framework for evaluating material service performance in high-temperature molten salt environments from three dimensions: thermal-induced phase transformation mechanisms, decoupling of mechanical property influencing factors, and zone-specific corrosion behavior in service environments. This work presents innovative solutions for the design and engineering application of structural materials in molten salt environments.

The first authors of these papers are Jinyao Jiang and Zhiwen Liu, jointly trained master's students of SINAP and Shanghai University (Supervisor: Prof. Huigai Li). The corresponding author is Dr. Jianping Liang of SINAP.